Trust our experience and innovative approach to the production of steel structures, and see that we carry out projects according to the expectations and requirements of the most demanding customers.

We guarantee that every step of the work is based on professionalism, timeliness and the highest quality workmanship. Discover the potential of working with us and realize your projects with a partner you can rely on.

We specialize in metalworking, combining modern technologies and proven methods. We offer comprehensive solutions for customers who are looking for high quality and precision in their projects. We have experienced welders on our team, so we can guarantee solid and durable structures.

We perform:

- Steel structures of warehouses, production halls, industrial halls,

- Steel structures of commercial, sports and public facilities,

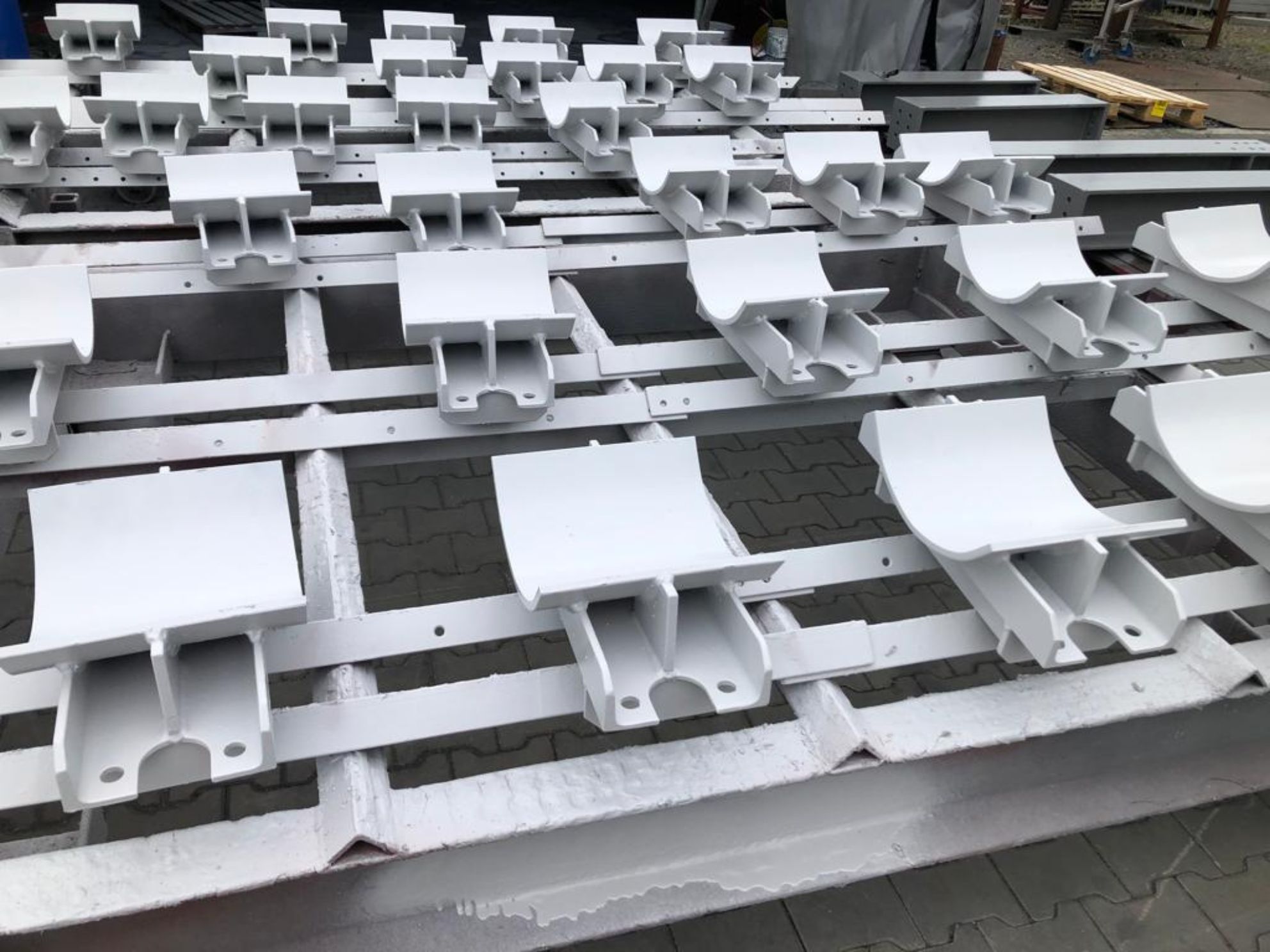

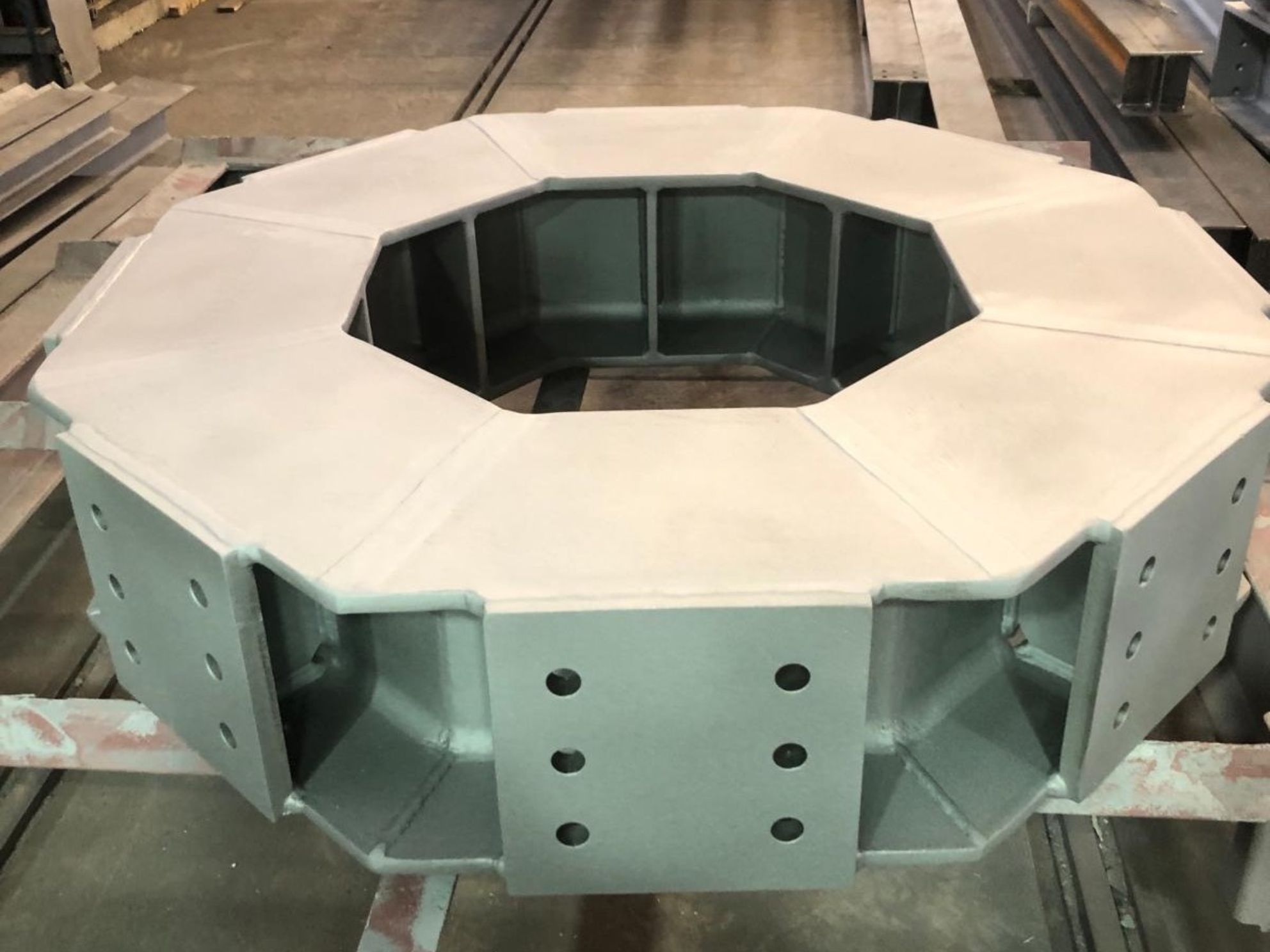

- Industrial and infrastructure structures such as pipeline components, pipe segments, pipeline supports, clamps, brackets, etc.

- Steel tanks, silos, garbage cans and hoppers.

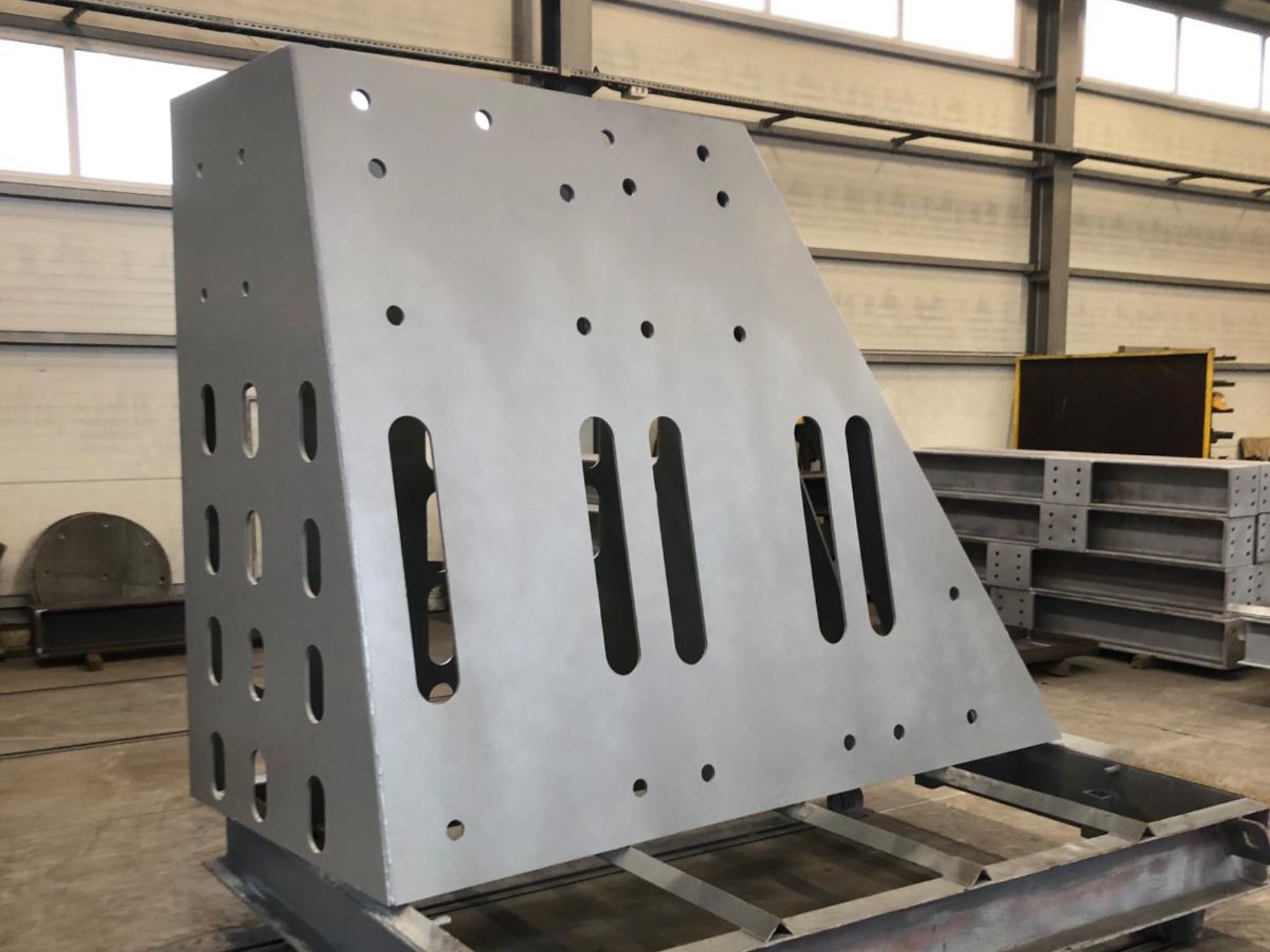

- other steel products such as transport pallets, substructures for machinery and other equipment.

We have a certified Factory Production Control system, so our products are made in accordance with EN 1090-2 and ISO 3834-2 standards and are delivered with a declaration of performance and CE marking.

We approach each order with commitment. We are happy to carry out even the most demanding orders.

We weld steel structures using the following methods:

– MMA 111 – manual arc welding with covered electrode;

– MAG 135 – arc welding with fusible metal electrode in active gas shielding;

– MAG 138 – arc welding with consumable electrode in active gas shield with metallic core powder wire

– TIG 141 – welding with tungsten electrode in a shield of inert gases

The welding technologies used enable the fabrication, installation and repair of steel structures from such steels as:

– low-carbon structural steels (S235J2 ÷ S355J2);

– austenitic and chromium corrosion resistant steels

– duplex

We have equipment from manufacturers such as Kemmpi, Esab, Lincoln, Böhler

We have a machine park that allows us to process metals adapted to the production profile.

We have at our disposal:

– GEKA HYDRACROP 55 sheet metal and profile cutting and punching machine;

– Band saws for cutting profiles;

– milling machine;

– Drilling machines (radial, column, table, caddy);

– drills on a magnetic foot;

– Karmak horizontal hydraulic press – 50 tons.

All application work, is carried out in accordance with the provisions of the current standards based on the latest technology and years of experience. Thanks to our cooperation with all the most well-known manufacturers of paint and fire protection coatings, as well as the great commitment of our crew and production engineers, we meet the requirements of the most demanding customers at every stage of anti-corrosion services, from technical support during the design, execution of protective coatings, to supervision and full warranty service.

All orders carried out, are confirmed by a certificate of paint quality and a report on the painting process.

We have a blasting chamber for blast cleaning of structures and a spray booth for painting steel elements by hydrodynamic spraying with internal dimensions of 12m x 4m x4m.

We use proven paint systems from manufacturers such as Teknos, Sika, Sherwin-Williams and others according to customer needs.

We assist our customers in selecting the optimal system for corrosion protection of structures.

We sincerely welcome your inquiry and order.

Experienced installation brigades and construction machinery equipment facilities, allow for comprehensive implementation of any project.

We are able to meet the expectations of the most demanding customers, from the preparation and manufacture of the structure to its installation.

The installation of steel structures performed by us meets the requirements of Polish and European standards.

Certifications and standards are not just paper confirmation,

But our promise of quality, safety

and sustainable development.

We make sure that every detail is perfected In accordance with the highest industry standards.

Discover why our partners recommend our company

and find out how we can meet your expectations.